Spray Foam Contractor Hobbs NM

Spray Foam Contractor Hobbs NM

Blog Article

Upon choosing Sunbelt as your insulation specialist in Odessa, TX, you receive systems crafted for West Texas' tough climate and constructed for long-term performance. Look forward to detailed application that seals gaps, fights moisture, and minimizes energy waste in both homes and businesses. Their local team handles permits, compliance, and safety throughout the process, focusing on durability and comfort. You'll learn how Sunbelt's demonstrated experience brings improved comfort and reduced energy costs—discover more about what distinguishes their service today.

Essential Takeaways

Why Choose Spray Foam Installation for Your Property in Odessa

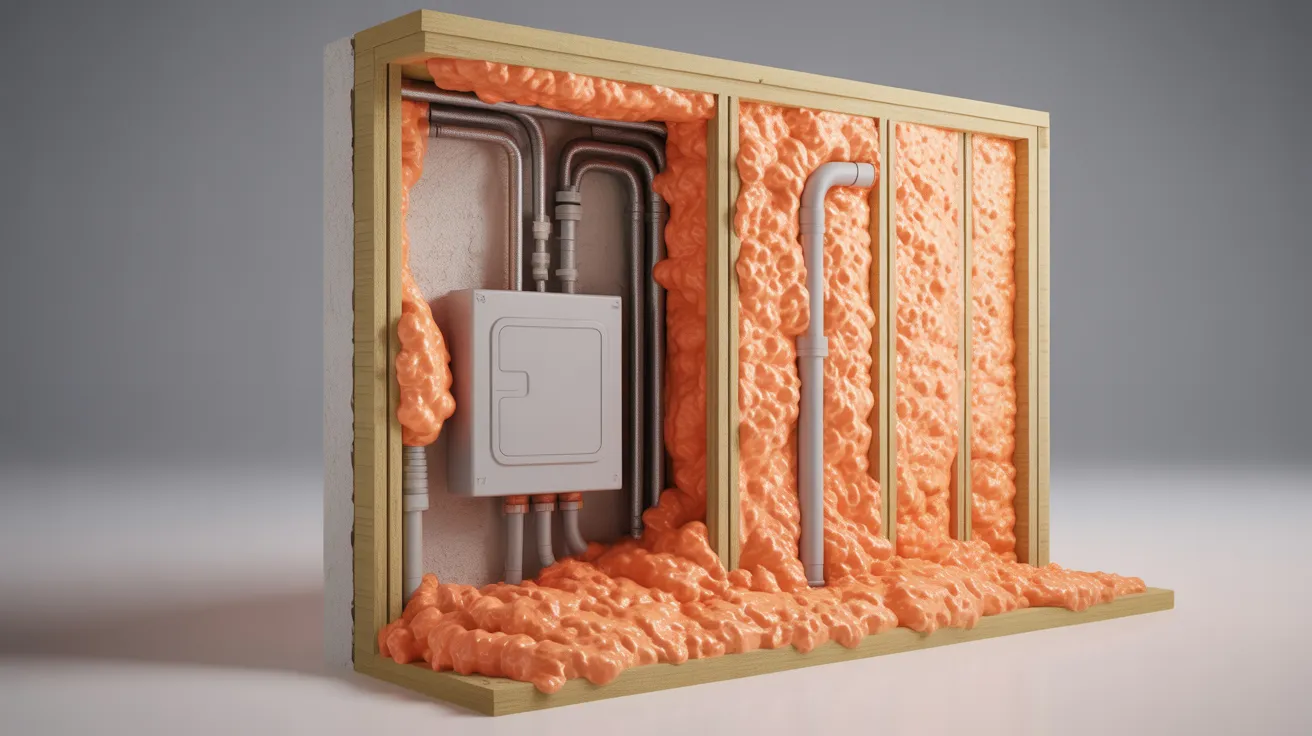

When you're looking to maximize energy efficiency and comfort in your Odessa property, spray foam insulation proves to be a superior solution. You'll value its exceptional insulation durability, offering a durable barrier that prevents settling, sagging, and moisture intrusion. In contrast to traditional materials, spray foam adapts to irregular cavities, ensuring a complete airtight seal that prevents drafts and air leaks. This spray foam versatility allows you to protect walls, attics, crawl spaces, and including hard-to-reach areas successfully. By choosing spray foam insulation, you're opting for a product that handles Odessa's extreme temperature swings and retains its performance over time. With reduced thermal gaps and improved resilience, your property continues to be consistently comfortable while decreasing energy waste and ongoing maintenance concerns.

The Advantages of Choosing a Trusted Odessa Contractor

When you work with a local Odessa spray foam contractor, you can leverage experts who are familiar with the region's particular climate challenges and building codes. Local knowledge guarantees your insulation solution withstands West Texas temperatures, dust, and seasonal variations. Contractors experienced with Odessa's specific requirements simplify permitting and inspection processes, decreasing project delays. You'll benefit from precise recommendations on materials and application techniques adapted to local conditions, enhancing energy efficiency and performance. Working with a nearby team also supports community growth, as your investment stays within Odessa's economy and builds local relationships. If issues arise, local contractors can respond quickly, delivering reliable follow-up service. Finally, selecting a local Odessa expert guarantees your project achieves the highest standards and delivers long-term value.

Sunbelt's Residential Spray Foam Solutions

Want to learn how Sunbelt can upgrade your home's energy performance? Sunbelt's residential spray foam services provide complete insulation for your home's key areas, substantially lowering utility expenses and energy waste. Their expert team applies advanced spray foam technology that fills and seals minor cracks, blocking air leaks and dampness. You'll appreciate improved acoustics and more consistent indoor temperatures. Sunbelt values spray foam safety by selecting low-VOC products and maintaining strict safety standards for your family's safety. They'll explain the spray foam investment, assessing your home's requirements and presenting clear estimates. Whether you're renovating an older home or building new, Sunbelt certifies each installation meets rigorous standards for effectiveness and reliability, giving you long-term benefits and assurance.

West Texas Commercial Insulation Solutions

Even though West Texas presents special concerns for commercial buildings—extreme temperatures, dust, and high energy demands—Sunbelt delivers specialized spray foam insulation systems that address these specific needs. You'll gain cutting-edge insulation that establishes a uninterrupted barrier, markedly boosting thermal regulation in commercial spaces, industrial buildings, and office complexes. Our team assesses your building's specific design and susceptibility to environmental stressors, then applies spray foam carefully to reduce air leaks and dust accumulation.

We also prioritize moisture control, ensuring your property is safeguarded against water damage, mold formation, and condensation issues in West Texas's dynamic climate. Sunbelt's thorough approach ensures all corners and spaces receives proper coverage, optimizing efficiency. With our technical experience, you can count on insulation that's built to endure the region's most challenging conditions.

Understanding Energy Efficiency and Cost Savings

Spray foam insulation will help you see reduced energy costs due to its exceptional thermal resistance. It forms an airtight seal that prevents heat transfer and provides energy efficiency far superior to conventional materials. This solution directly addresses your desire for cost-effective, long-term energy savings in the demanding Odessa climate.

Decrease Your Energy Expenses

When you invest in spray foam insulation in your Odessa, TX home, you'll notice a significant reduction in your monthly utility bills. Spray foam's outstanding thermal resistance establishes a robust barrier against heat transfer, minimizing the workload on your HVAC system. By closing gaps and cracks, spray foam blocks conditioned air from escaping, so your heating and cooling systems operate more efficiently and more effectively. This translates directly into decreased energy consumption and minimized costs. Furthermore, effective moisture read more control means fewer humidity-related issues, which can otherwise strain your HVAC and lead to increased expenses. With Sunbelt's professional installation, you're not just enhancing comfort—you're making a practical, solution-driven investment that provides benefits through considerable utility savings every month.

Optimized Thermal Effectiveness

Beyond lowering your utility bills, spray foam insulation provides a substantial boost in overall insulation performance for Odessa homes. You get a complete air seal that cuts down on heat transfer far more effectively than traditional insulation. This reliable seal limits drafts, preserving indoor temperatures balanced and HVAC systems operating optimally. Because spray foam fills up gaps and hard-to-reach spaces, it prevents weak points that affect energy efficiency.

Material longevity is a crucial benefit. Spray foam retains its integrity and performance long-term, ensuring lasting insulation efficiency for decades to come. This durable protection minimizes upkeep and replacement requirements, which decreases your property's ecological impact. By optimizing both energy consumption and material longevity, spray foam insulation provides an intelligent, eco-friendly choice for Odessa properties.

The Spray Foam Installation Process: A Step-by-Step Guide

Upon scheduling spray foam installation, your contractor will begin with an extensive site assessment to identify any challenges. Following this, technicians apply the foam with precision and monitor curing to ensure ideal performance. Once cured, they'll carry out a comprehensive inspection to verify quality and airtight coverage.

Site Planning and Initial Review

Prior to beginning spray foam insulation, a complete site assessment and preparation ensures the best safety and results. Begin by clearing the workspace of debris, dust, and any obstacles that could block access. Examine all surfaces for evidence of water, leaks, or water damage—proper moisture control is essential to stop mold formation and guarantee insulation performance. Next, assess the integrity of the structure and current insulation. Identify entry points, gaps, or cracks where air or moisture may infiltrate. Evaluate existing ventilation to maintain ventilation efficiency, as good airflow reduces condensation and maintains indoor air quality. Note any plumbing or electrical components requiring protection during installation. By managing these factors, you prepare for a successful spray foam application that satisfies quality and safety specifications.

Application and Curing Process

When site preparation is finished, the installation starts with heating and combining of the two essential components—polyol resin and isocyanate—in dedicated spray foam machinery. When the specialist sprays the compound on the specified surfaces, you'll observe rapid foam growth, permitting the material to thoroughly penetrate all spaces. This fast-acting process is essential for establishing a complete air and moisture barrier.

The curing process begins right away after application. After a short time, the foam solidifies, attaching strongly to the substrate. It's crucial to avoid disturbing or handling the area during this time to guarantee optimal results. Complete hardening optimizes insulation performance and structural integrity. When the foam has fully hardened, it provides a resilient, reliable solution tailored to your specific needs.

Post-Installation Inspection Steps

When the spray foam has finished curing, a thorough post-installation inspection becomes essential to confirm the integrity and quality of the application. You'll need to examine for even application, strong bonding to all surfaces, and freedom from gaps or voids. Closely monitor areas around electrical fixtures and penetrations, ensuring the foam doesn't compromise fire safety standards. Inspect the thickness of the foam to confirm it meets code requirements for insulation and air sealing. Review fire safety by verifying the application of any required ignition barriers. Furthermore, assess for off-gassing or odors that may indicate environmental impact issues. Document all findings and resolve any deficiencies immediately. This systematic approach confirms your spray foam installation performs safely and efficiently for years to come.

Quality Assurance and Safety Standards at Sunbelt

In providing exceptional spray foam insulation, Sunbelt maintains strict quality assurance and safety standards to secure both your property and our team. You benefit from our commitment to fire safety, as we employ foam products certified and evaluated for their fire resistance in adherence to industry codes. Our technicians follow strict protocols for safe material handling, guaranteeing proper ventilation and personal protective equipment during all steps. We also focus on material durability, selecting spray foams with established longevity and resistance to moisture and pests. Quality checks are integrated into each step, from surface preparation to final inspection, so you receive a reliable, long-lasting insulation solution. With Sunbelt, you can be confident that safety and performance continue as our top priorities on every project.

Customer Reviews and Project Achievements

How can you measure the actual impact of insulation? You'll discover the answer in the voices of clients who've witnessed the difference directly. Home and business owners in Odessa consistently highlight how Sunbelt's commitment to green materials and advanced techniques delivers measurable results. They've experienced substantial decreases in energy costs, enhanced indoor comfort, and improved property value—all supported by thorough project data and before-and-after visuals.

Customers praise the technical expertise of Sunbelt's team, showcasing meticulous execution and careful project coordination. A commercial customer shared stable interior climate in difficult industrial environments, thanks to exceptional spray foam installation. One residential client reported quieter interiors and better air quality. These project success stories underscore how choosing the right contractor creates long-term value in performance and efficiency.

Begin Your Journey: Getting a Free Quote From Sunbelt

Once you're prepared to experience the benefits of advanced spray foam insulation, Sunbelt simplifies the process with a straightforward and transparent estimate request. You'll begin by reaching out to their expert team—either online or by phone—to talk about your project's unique requirements. Sunbelt's professionals will ask specific questions about your building, insulation goals, and any concerns regarding spray foam safety or insulation durability. They'll set up an on-site evaluation to accurately evaluate your space and suggest the ideal insulation solution. After the evaluation, you'll receive a complete, itemized estimate explaining material specifications and application methods, so you can make an educated decision. Sunbelt's method guarantees you grasp every step, emphasizing both safety and long-term performance from the initial estimate to the final installation.

Common Inquiries

How Long Can You Expect Spray Foam Insulation to Last?

When you choose spray foam insulation, you're securing outstanding insulation durability and foam longevity. Generally, spray foam insulation performs for 20 to 30 years, but you might see it perform well beyond that with proper installation and maintenance. There's no concern over settling or drooping, as spray foam forms a rigid barrier. Its resistance to moisture, mold, and pests further guarantees that your insulation remains efficient for decades, maximizing your home's energy efficiency.

Are People With Allergies Safe Using Spray Foam Insulation?

If you suffer from allergies, you should consider both allergy triggers and chemical safety when picking spray foam insulation. After complete curing, spray foam generally doesn't release harmful chemicals or allergens, making it safe for most people with allergies. However, throughout the installation process, sensitivities may be triggered by chemical off-gassing. To guarantee safety, stay out of the area until the curing process completes—usually 24–48 hours—and work with an installer who maintains comprehensive safety and ventilation standards.

Is Spray Foam Installation Possible in Existing Walls?

Wait until you discover how substantially spray foam can transform your home's energy efficiency—even in existing walls! You can absolutely have spray foam installed in those walls, along with attic insulation and pipe insulation. Professionals utilize specialized equipment to apply foam through small access holes, ensuring thorough coverage without major demolition. This approach blocks drafts, enhances insulation performance, and prevents air leaks, delivering unmatched insulation performance and long-term savings. It's transformative!

What Are the Maintenance Requirements for Spray Foam Insulation?

Spray foam insulation requires minimal maintenance due to its durability and extended lifespan. It's important to check periodically for moisture problems or damage, particularly after any roof leaks or home improvements. Address any visible cracks or gaps immediately to preserve energy efficiency. Always monitor for pest activity and water issues, as these can degrade the foam's effectiveness. Routine inspections help guarantee your insulation's long-term performance.

How Does Spray Foam Impact Sound Reduction?

Envision creating a haven of quiet in your living space—while spray foam insulation provides outstanding soundproofing advantages, it's not a magic fix for absolute silence. You'll observe a diminishment in airborne acoustics, due to its compact structure. However, remember, insulation versus soundproofing is not the same; spray foam mostly stops air and thermal transfer, not all sound frequencies. For maximum soundproofing, you need to pair it with solutions particularly created to absorb and dampen vibrations.

Final Thoughts

Selecting Sunbelt as your spray foam contractor in Odessa is comparable to putting a premium engine in your property—it all operates more efficiently. You'll experience decreased energy expenses, enhanced living conditions, and lasting performance. Our team's specialized experience makes certain every installation meets the highest industry standards. When you need insulation solutions designed for West Texas, count on Sunbelt to provide solutions. Get in touch today for your complimentary quote and experience the difference industry experts can make.

Report this page